Diploma in Engineering Technology (Machine Tools Maintenance)

- Overview

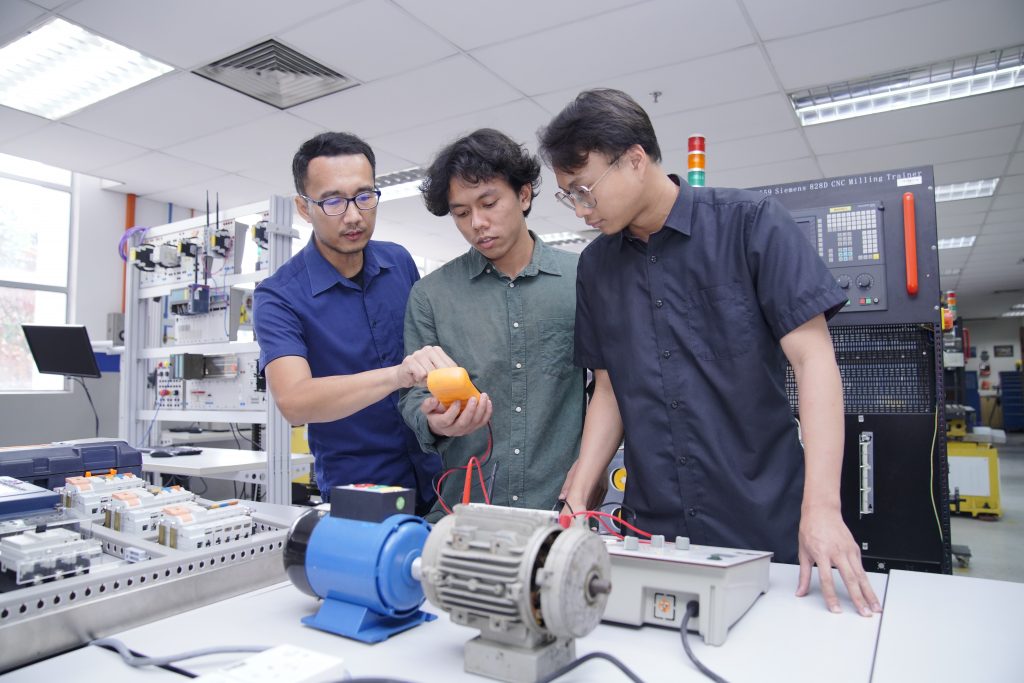

Machine Tools Maintenance Programme

Driven by a number of factors, including the migration from manual to CNC machine tools, higher production rates and higher quality requirements in which reducing machine tool downtime and assuring quality have become increasingly important as the demand for higher production rates and closer tolerance continue to grow. Other that learning about how each part of the machine functions in relation to the overall machine process, the students will be equipped to develop and conduct a preventive maintenance programmes that will maximize the machine tool performance.

Programme will cover:

Standard services that includes a thorough inspection of the machine’s key components and mechanical systems for which the graduates will perform tasks such as maintenance, cleaning, tightening and lubrication of the mechanical and electrical components. The comprehension of the entire infrastructure of machine tools will allow the graduate to earn the competency in comprehensive machine maintenance and repairing services.

Program Code:

(R2/0741/4/0008) (12/29) (MQA/FA 4786)

Status: Accredited

Fee: RM 33,324

(Education Fee Only)

Study Mode: Full Time

Duration: 6 Semester/ 3 Years

- Able to demonstrate skills in machine tools maintenance particularly in areas related to mechanical and electrical machine services, assembly, modification and performance, thus contribute to local and global industry demands

- Able to engage in lifelong learning and demonstrate good leadership quality through academic qualifications achievement and career advancement

- Responsible to the community, cultures and environment through involvement with related organizations and society

- Able to communicate effectively and demonstrate entrepreneurial skills

PLO 1 Knowledge:

Apply knowledge of mathematics, science, engineering fundamentals and engineering specialisation principles to well-defined practical procedures and practices

PLO 2 Analyse:

Analyse well-defined engineering problems in their discipline or area of specialisation

PLO 3 Well-defined Technical Problems:

Formulate solutions to well-defined technical problems

PLO 4 Systems, Components or Process:

assist in formulation of systems, components or processes to meet specified needs

PLO 5 Well-defined Problems:

conduct investigations of well-defined problems

PLO 6 Techniques, Resources and Engineering:

Apply appropriate techniques, resources, and engineering tools to well-defined engineering activities, with an awareness of their limitations

PLO 7 Awareness and Consideration:

Demonstrate an awareness of and consideration for societal, health, safety, legal and cultural issues and their consequent responsibilities

PLO 8 Effective Communication:

Communicate effectively with the engineering community and society at large

PLO 9 Technical Team:

Function effectively in a diverse technical team

PLO 10 Professional Ethics, Responsibilities and Norm:

Demonstrate an understanding of professional ethics, responsibilities and norms of engineering technology practices

PLO 11 Management, Business Practices and Entrepreneurship:

Demonstrate an awareness of management, business practices and entrepreneurship

PLO 12 Impact of Engineering Practices:

Demonstrate an understanding of the impact of engineering practices, taking into account the need for sustainable development

PLO 13 Independent and Lifelong Learning:

Recognise the need for professional development and to engage in independent and lifelong learning

- Field Service Machine Maintenance

- Assistance Engineer

- Machine

– Designer and Retrofitting (Executive)

– Designer

– Expert

– Associate

– Automation Specialist - Maintenance

– Manager (Executive)

– Engineer

– Planner Scheduler

– Mechanic

– Administrative Specialist - Project Assistant Engineer (Executive)

- Engineering Supervisor (Executive)

- Operation Engineer

- Precision Machine Tool Mechanic

- Industrial Maintenance Technician Instructor

- Machine

– Repair, troubleshooting & retrofit

– Maintenance and refurbish

– Modification and Improvement

– Design - Machine and Factory Maintenance Management

- Factory Engineering Maintenance and Operation

| Course | |

| Semester 1 |

|

| Semester 2 |

|

| Semester 3 |

|

| Semester 4 |

|

| Semester 5 |

|

| Semester 6 |

|

- Other Information

+60389219000

marketing@gmi.edu.my - Programme Information

+60 12 – 3812029

Gallery

March 2025:

2024 and the preceding years: